The Best Products

What Is The Production Process For Medical Cotton Swabs?

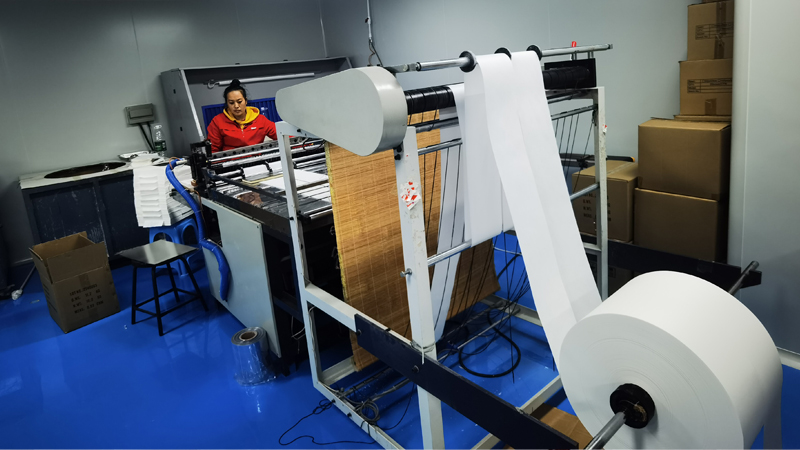

To purchase qualified cotton swabs and cotton swabs, the first step is the production process of medical cotton swabs. The cotton swabs are crushed into cotton fibers through a cotton crusher, and then evenly conveyed forward. At the same time, the cotton swab rod and cotton fibers are conveyed forward together, so that the head of the cotton swab rod rolls onto the surface of the first rubber wheel coated with cotton glue. Dip the cotton swab head with cotton swab glue, make the cotton swab head in contact with the cotton fibers, rotate the cotton swab stick, wrap the cotton thread around the swab head, and the cotton fibers on the cotton swab stick squeeze the first shaping plate, quickly rotate it on the first shaping plate, so that the cotton fibers on the cotton stick are initially formed. Use the shaping glue to roll the cotton fibers onto the surface of the second rubber wheel coated with the shaping agent, so that the cotton fibers roll out and the surface of the cotton fibers is coated with the shaping agent, The cotton fibers on the cotton swab are squeezed into the second forming plate and quickly rotated. Forming the cotton fibers on the cotton sliver; The formed cotton strips are dried.

Wrap the dried cotton swabs on the coating, and then accurately count them in a packaging bag, without sterilization, before packaging. Re pack the packaged cotton swabs into cardboard boxes and then enter the medical cotton swab sterilization workshop, which usually takes about 7-15 days for sterilization. Send out after arrival at the warehouse.