The Best Products

The Production Process Of Cotton Swabs

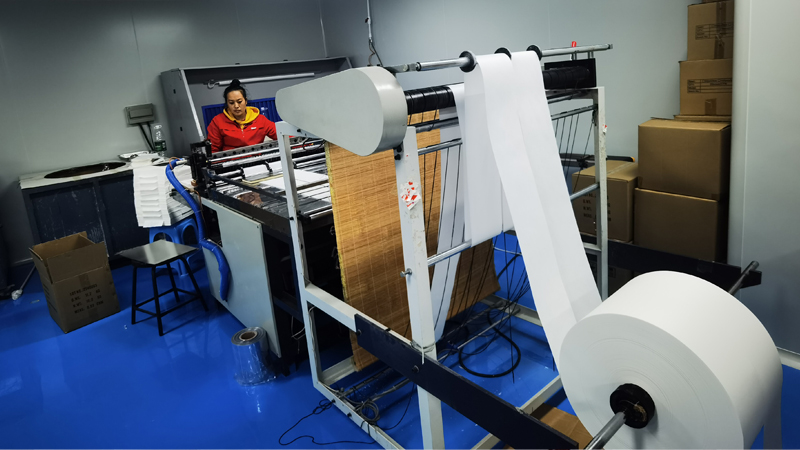

Firstly, the cotton used to make cotton swabs is poured into a feeder, where bundles of cotton are separated into individual fibers. The carding machine combs the cotton through a huge roller, and then forms a uniform thickness of cotton cloth through a gravity sensor. It is then cut into uniform sized cotton strips through a slitting machine. Here, some cotton strips are printed with patterns and made into cotton sheets for unified packaging, while others are used to make cotton swabs. These cotton strips pass through a funnel, which changes their shape from flat to circular and sends them to one end of the cotton swab, wrapping them around one end of the swab. The amount of cotton used on each cotton swab will vary depending on the customer's customized specifications.

The heating device inside the device will heat one end of the plastic rod and roll the cotton thread onto the plastic rod. Of course, if it is a wooden cotton swab stick, it needs to be coated with glue at the front end and then sterilized and disinfected. Here, unqualified cotton swabs will be removed. Finally, the uniform specification and quantity of cotton swabs will be uniformly packaged using a robotic arm, and then they will be transported to various parts of the country.